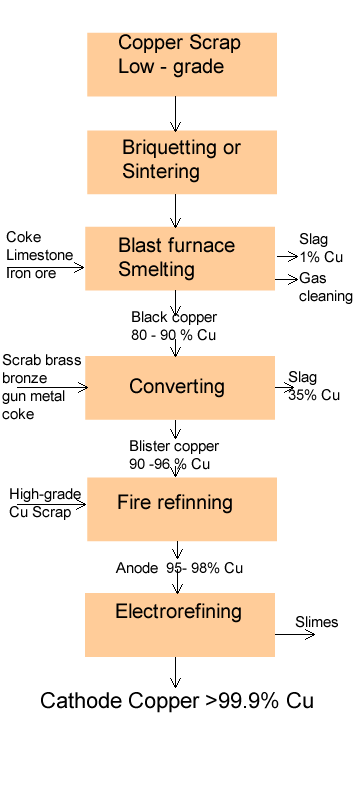

Recycling is a major source of copper in the industries. The copper scrap originates from foundries, fabricators and user industries. The scrap dealers sort out the scrap according to the grade and composition. The wire and cable manufacturers have their own facility or remelting facilities. Normally, a rotary type furnace that is 5-7m in length and 3m in diameter is used to melt and cast the copper for rerolling to wire rods. Figure 1 is shown for the recovery of low grade scrap copper.

Recycling of waste metals

Secondary metals are those that are recovered from scraps, slimes, dusts, slags and waste materials. Generally the recovery of metals from waste materials require far less energy than that required for production from the primary ore. Some metals are produced only through recycling method and called as By Product such as Se, Te, Cd and Bi.

The reasons of using recycling methods are:

- Decries of row materials in the world

- Using of recycling is economical

Recycling need less energy (table 1)

| Metal | Primary from ore(106 kcal/ton) | Recycling(106kcal/ton) |

| Mg | 90.2 | 3 |

| Al | 61.5 | 3 |

| Ni | 36.3 | 3.8 |

| Cu | 28.2 | 4.3 |

| Zn | 16.4 | 4.3 |

| Steel | 8.1 | 3.3 |

| Pb | 6.8 | 3 |

Copper

Aluminium

Scrape aluminium is a major source in the industries for example: Turnings, borings, trimmings, foils and cans, these called new scraps and it doesn't need a beneficiation process. These are cut with special and is melted In a rotary furnace at about 600 oC .A melted salt is used in this process such as: flurried flaxes:AlF3,NaF,KCl,NaCl,Na3AlF6.This salt protect the molten metal against air and humety.

The percentage of salts can be as follow:

- 5-15 % Na3AlF6, 50-60% NaCl and 30-40% KCl

- 45% NaCl, 45%KCl and 10% NaF

The impurities are removed through Segregation process as Al3Fe, boride and etc. Mg is removed through Cl2 gas as MgCl2.

Iron

There are two sorts of scrap iron:

- New scrap: It is scrap, which is produce in the machinery industries and because of their good quality ,it will be used directly in the production of steel in converter or arc furnace industry.

- Old scrap: It is scrap, which get from old products such as wash machine, fridge and etc. In this material can exist some another materials such as rust, corrosion and plastic parts. These materials must be cut (Scrap shredders) and refined from waste materials such as Cu, Co, Ni, Mo and etc. Some materials are burned in a scrap burning to remove wood ,plastic and oil. Sometimes it is to use a powerful hammer for bricking the old scraps. After this process, it is produced a charge for the production of steel.